So today I wandered down to Warhammer World to pick up a Captain Stern to finish my little Grey Knights force (all metal, except Stern, who I forgot to buy back in the day). It has to be said, I expected QA issues, and I wasn't disappointed.

The clear back of packaging on the blisters/clamshells is essential. It took FIVE packs (this being the sixth) before I found a model that didn't have either pieces of torn mould material caught in places, air bubbles or vents obscuring detail, or other fairly obvious casting flaws. I wanted to review the best of the bunch. This is it.

As ever, click any of the images for a larger view.

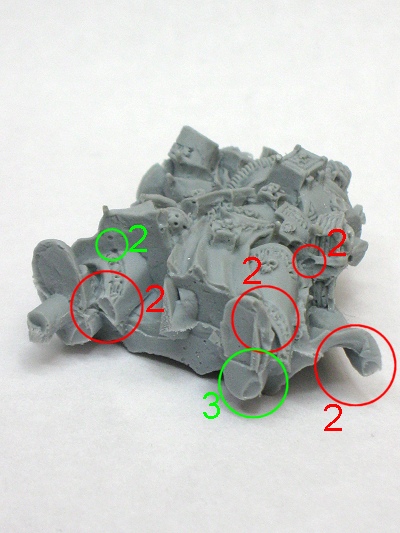

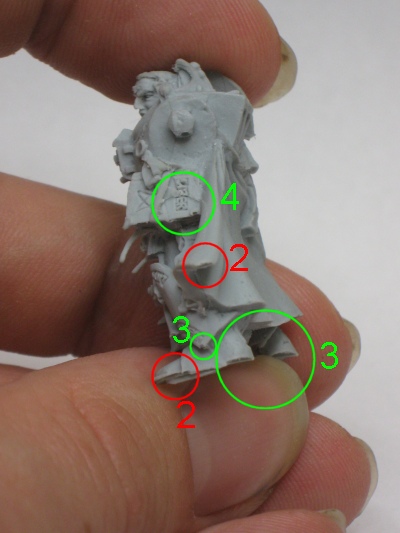

LABELLED FLAWS:

MAJOR / HARD FIXES (RED CIRCLES):

I would not expect ANY flaws of this type on a professionally produced and QA'd miniature.

1) Warping of parts requiring resculpt or putty work. The face needed a tweak to the nose, and the lens on the armour was so far off circular, it had to be remade.

2) Large bubbles requiring resculpting work. Particularly the bottom of the feet, and corner of the cloak. Some of these are actually quite tricky to spot without having the model off the sprue.

MINOR / EASY FIXES (GREEN CIRCLES):

I would expect to see one or two of these on a decent quality miniature. By comparison, Forgeworld casts I've worked on usually have three or four instances.

1) Vent points obscuring detail. Sometimes this is unavoidable in casting. Here, one of the lugs on the chest reliquary had a vent that obscured the groove around it.

2) Minor surface bubbles. Fairly common in resin casts, and best fixed with a surfacing putty. Finecast has issues with these (more than a harder polyurethane resin) as it doesn't particularly like being sanded, so any repair has to be surfaced OVER the finecast, or it can remain visible once paint goes on. Vallejo's plastic putty is great.

3) Minor bubbles / voids that require a sculpting putty fix. Break out the greenstuff. I really wouldn't expect to see these slip past QA unless they're really easy to fix, and then perhaps only one. In these cases the heels needed building up and surfacing.

POSITIVES:

VERY COOL - Crisp detail. Soft mould material lets fine surface detail get cast nicely.

VERY COOL - Easy carve material. Very much similar to set greenstuff in consistency. Similar behaviour from first tests.

COOL - Thermally responsive. Hot water and cold (ice) water can be used to soften and set the resin to correct bends and (within limits) heat stretch / straighten. Too hot and it gets very soft very quickly - a few seconds is all it needs.

MEH - Superglue absorbent. It's slightly porous and does indeed superglue very well. As it's lightweight the joints are self supporting pretty quick without the need to pin or use a CA catalyst.

I've categorised the flaws I see as red or green - red being tricky to fix (and best taken as impossible / best not attempted for a young'un), and green being easy enough in my opinion.

NEGATIVES:

UNBELIEVABLY, SHOCKINGLY DOUBLEPLUSVERY BAD - Disgusting QA. It took 6 packs to get this model, which was the least affected of the bunch. Several of the rejected models actually had mould material stuck to them. - You'll notice it as it's bright pink. And this is from Warhammer World. This is singularly the most major problem, and it's the primary negative in my opinion. All the easy gluing in the world won't save me time if I have to resculpt parts of EVERY. SINGLE. MINIATURE. From a 'pro painter's' standpoint, this alone is enough for me to recommend other companies' products in preference.

VERY BAD - Price. £14.50. NOT WORTH IT! For damn near 15 quid, I'd expect a much better production. I reckon this miniature is actually worth about £7.50, tops. Again, that's for the best out of 6 packs, taking the work involved in fixing it into account.

BAD - Vent points obscure detail in places. Again, requiring careful knife work to fix. Presumably due to the soft mould material.

BAD - Air trapped in the mould and or Warping leads to filling / sculpting work that whilst easy, shouldn't need to be done.

MEH - Flash present in odd places. Flash at the top of the cape needs to be carefully removed. Not really sure why it's there in the first place.

MEH - Some parts snapped off the sprue - No damage in this case, but easy to see where it could have happened. A simple piece of sponge in the pack would probably help that.

VERY BAD - Mould warping / air trapping is present in areas that are impossible to fix without resculpting part of the model.

BAD - Air bubbles in some places require reasonable-to-good sculpting and surfacing skills to fix - in particular, here the corner of the cloak on the left side is missing. A surfacing putty (eg Vallejo Plastic Putty) is essential to smooth things in - the Finecast material does not like being sanded with anything other than a feather touch.

Overall score: 4/10. Potentially a nice change, but the QA really needs to be stepped up a LOT for the price to be worthwhile. For the time being I'll advise clients against mail / internet ordering (as I do for Forgeworld stuff), and instead offer to go pick it up in store for them so the quality can be checked. By someone who cares.

My first Finecast model was... disappointing.